Mathematical Optimization of Data-Driven Production Planning Based on Production Planning Environment Characteristics for Product Tracking and Delay in the Biopharmaceutical Industry

Keywords:

Data-driven production planning, mathematical optimization, genetic algorithm, biopharmaceutical industryAbstract

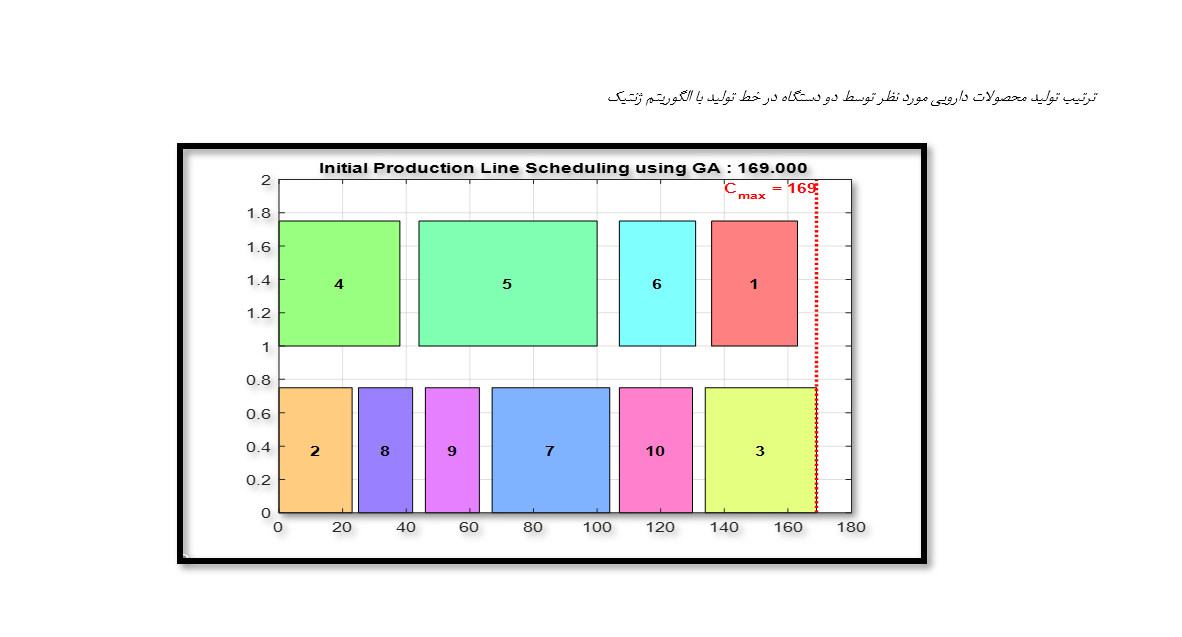

Data-driven production planning, by leveraging modern technologies such as artificial intelligence, machine learning, and big data analytics, enables the optimization of production processes, improved demand forecasting, and effective resource management. In the biopharmaceutical industry, which faces considerable uncertainties such as market fluctuations, supply chain complexity, and qualitative changes in production, the adoption of data-driven approaches can create a significant competitive advantage. Recent studies have shown that many companies encounter major challenges in adopting data-driven technologies and planning for data-driven production. Much of these difficulties are related to the characteristics of the production planning environment; therefore, understanding these characteristics is essential for identifying the needs and opportunities of data-driven production planning. Accordingly, the primary objective of this article is to propose an optimization model for data-driven production planning based on the characteristics of the production planning environment in the biopharmaceutical industry. In the present research, a case study (descriptive–mathematical) was conducted in the pharmaceutical industry. Data were collected through observations and visits to production sites, workshops, meetings, and formal interviews with production managers and planners, supply and technology managers, innovation managers, and production line engineers. The problem data were analyzed using CPLEX GAMS 24.4 software and a genetic algorithm implemented in Matlab R2022b. Ultimately, a conceptual, data-driven, and intelligent model (instead of the traditional model) of production planning based on production flexibility, intelligent systems, and expert systems is presented.

Downloads

References

Bueno, A., Filho, M. G., Carvalho, J. V., & Callefi, M. (2022). Smart Production Planning and Control Model. In A. Mesquita, A. Abreu, & J. V. Carvalho (Eds.), Perspectives and Trends in Education and Technology (Vol. 256). Springer, Singapore. https://doi.org/10.1007/978-981-16-5063-5_21

Bueno, A. F., Godinho Filho, M., & Frank, A. G. (2020). Smart production planning and control in the industry 4.0 context: a systematic literature review. Computers & Industrial Engineering, 106774. https://doi.org/10.1016/j.cie.2020.106774

Chien, C. F., & Chen, Y. J. (2022). Data-driven smart manufacturing: Applications, trends and challenges. Journal of Manufacturing Systems, 62, 279-290.

García, E., Hoon Kwak, D., Jeong, Y., & Wiktorsson, M. (2024). Machine learning in smart production logistics: a review of technological capabilities. International Journal of Production Research, 1-35. https://www.researchgate.net/publication/382464697_Machine_learning_in_smart_production_logistics_a_review_of_technological_capabilities

Gomez-Gasquet, P., Boza, A., Perales, D. P., & Esteso, A. (2024). A Deep Reinforcement Learning Approach for Smart Coordination Between Production Planning and Scheduling. In R. Rodríguez-Rodríguez, Y. Ducq, R. D. Leon, & D. Romero (Eds.), Enterprise Interoperability X (Vol. 11). Springer, Cham. https://doi.org/10.1007/978-3-031-24771-2_17

Gupta, A., Singh, R., & Kumar, P. (2020). Data-driven approaches in biopharma production: A review. Biotechnology Advances, 45.

Javaid, W., & Ullah, S. (2025). Data driven simulation based optimization model for job-shop production planning and scheduling: an application in a digital twin shop floor. Journal of Simulation, 1-15. https://doi.org/10.1080/17477778.2025.2469687

Khuat, T. T., McShan, D., & O'Mahony, C. (2023). Machine Learning in Biopharmaceutical Process Development: Current Trends and Future Directions.

Lee, C., Park, J., & Choi, Y. (2022). Data-Driven Multi-Objective Optimization for Sustainable Pharmaceutical Production. Computers & Industrial Engineering, 169, 108141.

Lee, J., Kao, H. A., & Yang, S. (2021). Data-driven smart manufacturing. Journal of Manufacturing Systems, 58, 1-12.

Luo, D., Guan, Z., Ding, L., Fang, W., & Zhu, H. (2025). A Data-Driven Methodology for Hierarchical Production Planning with LSTM-Q Network-Based Demand Forecast. Symmetry, 17(5), 655. https://doi.org/10.3390/sym17050655

Mansouri Mosalou, F., Amiri, M., Taghavi Fard, M. T., & Haji Agha'i Kashteli, M. (2024). Design and Planning of Bioethanol Supply Chain Network with a Hybrid Data-Driven Robust Optimization Approach under Discrete Uncertainty Sets. Decision Making and Operations Research, 327-352. https://www.journal-dmor.ir/article_199979_en.html

Oluyisola, O. E., Bhalla, S., Sgarbossa, F., & Strandhagen, J. O. (2022). Designing and developing smart production planning and control systems in the industry 4.0 era: a methodology and case study. J Intell Manuf, 33, 311-332. https://doi.org/10.1007/s10845-021-01808-w

Oluyisola, O. E., Sgarbossa, F., & Strandhagen, J. O. (2020). Smart Production Planning and Control: Concept, Use-Cases and Sustainability Implications. Sustainability, 12(9), 3791. https://doi.org/10.3390/su12093791

Panjwani, N., Luben, D., Lin, N., Baksh, S., Ultee, M. E., Coffman, J., & Titchener-Hooker, N. J. (2024). Predictive modelling of cell culture performance for commercial biotherapeutics production using historical process data. Biotechnology and Bioengineering. https://doi.org/10.1002/bit.28813

Pascal, G., Tornillo, J. E., Rossit, D. A., & Redchuk, A. (2023). Data-Driven Production Planning and Supply Chain Management: A Brief Review. 2023 4th International Conference on Data Analytics for Business and Industry (ICDABI),

Radmehr, M., Abdollahzadeh Sangarudi, H., & Saheb Jamnia, N. (2020). An Integrated Mathematical Programming Model for Production and Distribution of Radiopharmaceuticals (Case Study: Pars Isotope Company). https://www.magiran.com/paper/2177619/an-integrated-mathematical-model-of-production-and-distribution-planning-for-radiopharmaceutical-products-case-study-pars-isotope-company?lang=en

Razavi. (2022). Optimization of Herbal Drug Production with Genetic Algorithm. Journal of Industrial Engineering of Iran.

Saldanha-da-Gama, F., & Wang, S. (2024). Data-Driven Robust Production Planning. In Facility Location Under Uncertainty (Vol. 356). Springer, Cham. https://doi.org/10.1007/978-3-031-55927-3_16

Sharma, A., Goyal, P., & Choudhary, A. (2021). Biopharmaceutical production: Challenges and recent trends. Biotechnology Reports, 31, e00685.

Su, X., Zeng, L., Shao, B., & Lin, B. (2025). Data-driven optimization for production planning with multiple demand features. Kybernetes, 54(1), 110-133. https://doi.org/10.1108/K-04-2023-0690

Thakur, M., Horst, J., Roth, A., & McNally, D. (2020). Biopharmaceutical production: Planning.

Tripathi, V., Chattopadhyaya, S., Mukhopadhyay, A. K., Saraswat, S., Sharma, S., Li, C., & Georgise, F. B. (2022). A novel smart production management system for the enhancement of industrial sustainability in Industry 4.0. Mathematical Problems in Engineering. https://doi.org/10.1155/2022/6424869

Völker, T., & Mönch, L. (2023). Data-Driven Production Planning Models for Wafer Fabs: An Exploratory Study. IEEE Transactions on Semiconductor Manufacturing, 36(3), 445-457. https://doi.org/10.1109/TSM.2023.3277410

Wang, L. (2023). Data-Driven Modeling Methods for Pharmaceutical Processes. Journal of Pharmaceutical Innovation, 18(1), 112-130.

Wang, S., Yang, G., & Liu, S. (2024). A data-driven multi-channel supply chain multi-factory collaborative production planning problem. Soft Comput. https://doi.org/10.1007/s00500-023-09546-2

Wang, Y., Ma, H., & Zhang, X. (2020). Data-driven production planning for smart manufacturing. Journal of Manufacturing Systems, 54, 321-330.

Zhang, Y., Liu, C., & Lv, J. (2020). Data-driven production planning and scheduling: A review. Journal of Intelligent Manufacturing, 31, 1749-1770.

Downloads

Published

Submitted

Revised

Accepted

Issue

Section

License

Copyright (c) 1404 Seyed Ghasem Salimi Zaviyeh; Abolfazl Kazazi, Iman Raeesi Vanani, Soroush Ghazinoori (Author)

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.